The dimensional accuracy of the metal stamping parts refers to the difference between the actual size of the stamping parts and the basic size. The smaller the difference, the higher the dimensional accuracy of the metal stamping parts. The deviation of dimensional accuracy of precision stamping parts is one of the common problems of stamping parts. The dimensional accuracy of metal stamping parts can be generally divided into two types: precision grade and ordinary grade.

The precision grade is the precision that can be achieved in the stamping process technology, while the ordinary grade is the precision that can be achieved by more economical means. When the mold manufacturing precision is high, the shape dimension accuracy of metal stamping parts can reach IT10 level, and the inner hole size can reach IT9 level.

Factors affecting the precision of metal stamping parts:

1,The quality of raw materials is poor.

2,The multi-process parts are improperly adjusted in the previous process or the corners are worn, which destroys the principle of equal volume when deformed and causes changes in dimensions after punching.

3,Due to poor positioning during operation, or poor design of the positioning mechanism, the blank has moved during the blanking process. Or the inaccurate positioning caused by the defects (prism, lack of edges, etc.) of the sheared parts can all cause the size to be out of tolerance.

4,The punching order is wrong.

5,The manufacturing of the cutting edge of the die is out of tolerance.

6,The spring back in the punching process of precision stamping parts, the shape of the workpiece in the previous process and the shape of the supporting surface of the working part of the mold in the next process are inconsistent, so that the precision stamping part is deformed during the punching process and the punching is completed After that, elastic recovery occurs, which affects the dimensional accuracy.

7,The shape is not good.

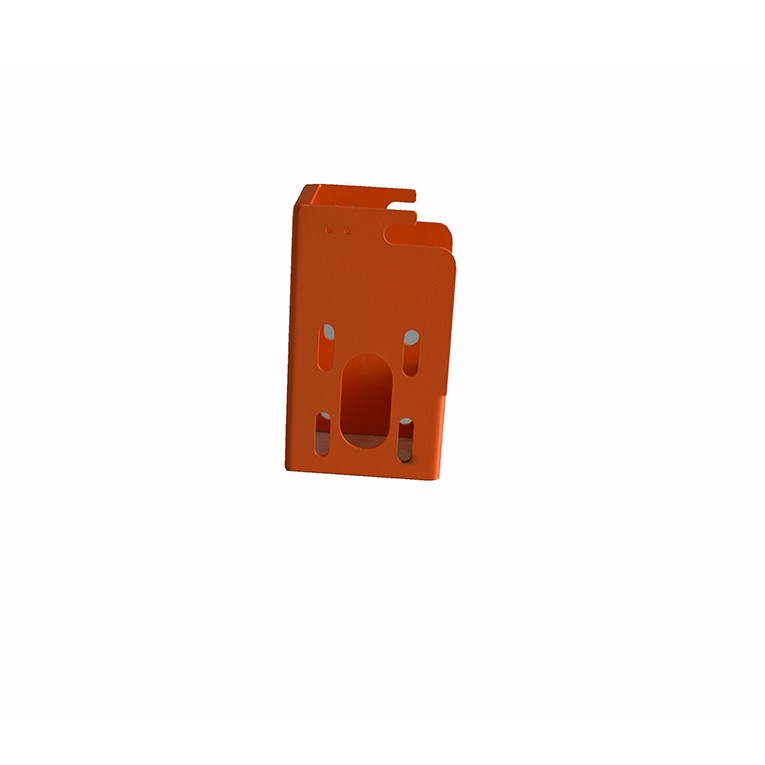

The processing of metal stamping parts includes blanking, bending, drawing, forming, finishing and other processes. The materials for stamping parts are mainly hot-rolled or cold-rolled (mainly cold-rolled) metal plate and strip materials, including alloy steel plates and carbon steel plate, spring steel plate, galvanized plate, tinned plate, stainless steel plate, copper and copper alloy plate, aluminum and aluminum alloy plate, etc.

Copyright © 2025 Dongguan Yifeng Metal Co., Ltd. | All Rights Reserved