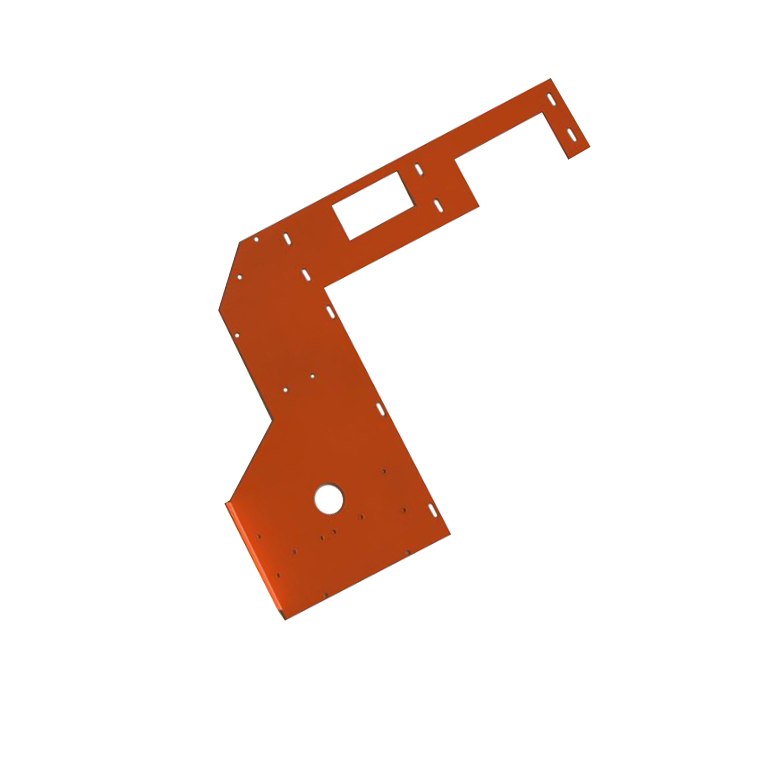

Sheet metal parts are products processed by sheet metal technology, and we cannot live without sheet metal parts in our lives. Sheet metal parts are manufactured by filament power winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, metal sheet bending, die forging, water jet cutting, precision welding.

1. Sheet metal parts processing methods:

Most of the sheet metal parts you see usually have textures. These textures are obtained after surface treatment, which can effectively protect the sheet metal parts from external factors,such as rust and denaturation. The surface treatment of gold is an important procedure for sheet metal processing.

Common surface treatment methods for sheet metal processing are wire drawing, sand blasting, paint baking, powder spraying, main technical indicators: gloss, film thickness and color difference, electroplating (mainly colorful zinc plating, white zinc, black zinc, chrome plating), polishing, oxidation.

2. Sheet metal processing methods:

In the process of sheet metal processing, the cutting process is used, and the overall process is very demanding for laser cutting. So how to deal with some problems in laser cutting in the process of processing the sheet metal shell?

A brief introduction to laser cutting technology in sheet metal processing. If you want to achieve a good sheet metal processing effect, you must use the perforation technology, and this technology requires perforation cutting in most cases.In the process of cutting, the blasting method cannot be used for punching,but the pulse method should be used to concentrate the energy on the surface of the sheet metal shell to obtain the effect of changing the aperture.

In the whole process of sheet metal processing, the cut part shell needs to be burred, which can more effectively ensure that the product can receive a smoother effect. In fact, in the process of sheet metal processing, it is necessary to choose high-quality plates, coupled with efficient processing methods to create a perfect sheet metal shell product.

Copyright © 2025 Dongguan Yifeng Metal Co., Ltd. | All Rights Reserved